Hardscaping is an art that transforms outdoor living spaces into stunning oases of beauty and functionality. Hardscape is the term used in landscaping to denote any flooring, wall, or elevated structure made out of stone. Flagstones, Patio Stones, Retaining walls, pool decking and coping, concrete, or stone steps are all considered hardscape material. Transforming these hardscape materials into beautifully transformed outdoor spaces requires planning, precision, and skill. Hardscape stone is linear and rarely does it fit into a gardens contours, curves, and edges. This is where stone saws play an indispensable role, cutting hardscape materials to fit into the perfect design. These specially designed saws along with their blades are distinctly created for cutting any hardscape material. For enthusiasts and professionals, understanding the intricacies of stone saws is essential for achieving the perfect cut while ensuring safety and efficiency. In this blog, we will delve into the safe operation of stone saws, compare electric and gas-powered options, explore the various kinds of stone saw blades, and discuss their use on different hardscape materials such as natural and precast stone.

Safe Operation of Stone Saws

Safety is paramount when operating any type of stone saw. Before starting any cutting task, always wear appropriate personal protective equipment (PPE), including gloves, eye protection, ear protection, and a dust mask to prevent inhalation of fine particulates. Ensure that the saw is on a stable surface and that the material to be cut is secure and will not move while cutting.

For both electric and gas-powered saws, it's crucial to inspect the equipment before use. Check for any signs of wear, ensure that guards are in place and functioning, and confirm that blades are sharp and securely attached. Never attempt to remove material or adjust the saw while it is in operation, and always refer to the manufacturer's manual for specific safety instructions related to your model.

Dry Cutting vs. Wet Cutting with Stone Saws

When it comes to hardscape cutting techniques, you have two primary choices: dry cutting and wet cutting, each with its own safety considerations and best-use scenarios. Wet cutting is a technique where the blade is cooled by water as it saws the stone. The water sprays directly onto the cutting surface. Wet cutting can reduce respiratory health risks by turning the concrete dust into sludge. Wet cutting typically uses a walk-behind saw and is often used in large-scale construction to cut through flat stone. It requires a continuous stream of water to prevent the blade from warping or losing segments. Wet-cutting saws operate at high revolutions per minute (RPM), which means they can cut longer. Because they use water, most wet-cutting tools run on either diesel or gasoline to prevent electrocution hazards. Generally dry cutting is only acceptable when making infrequent and shallow cuts as the stone saw and blade can create a tremendous amount of heat while dry cutting. Below is a list of advantages and disadvantages of both dry and wet cutting.

Dry Cutting:

Advantages:

Simple and Convenient: Dry cutting is convenient because it doesn't require a water source, which makes it more flexible in various job site conditions. Dry cutting creates shallow, straight cuts. It makes these simple jobs even more straightforward. While wet cutting requires a constant stream of pressurized water, dry cutting uses airflow to prevent overheating. Use dry cutting when there is no water source or when the job site needs to stay dry at all times, such as indoor construction.

Cleaner and Safer around other equipment: During wet cutting, water combines with dust, creating a stone slurry. While this minimizes dry particles in the air, it creates a mess to clean. Dry cutting creates a cleaner job site and can be combined with a dust extractor or vacuum to remove dust. Without water sprayed on the cutting surface, there is no chance of splashing. Dry cutting is less intrusive, meaning contractors can carry on with construction work, even with electrically-powered equipment, while the saw is in use.

Sharp detailing: A dry-cutting saw is known for detailing and finishing work and can create a flatter, smoother surface. It can score or create decorative patterns.

Longer-lasting blade: While all diamond blades are long-lasting, those designed for dry cutting are more durable and heat-resistant. Since they have no water source to provide cooling, these blades stay sharp for decreased maintenance.

Disadvantages:

Respiratory Dust: Dry Cutting produces a significant amount of dust, which can be hazardous. Always use a dust mask or respirator and operate in a well-ventilated area. For prolonged cutting, consider using a dust collection system to minimize airborne particles.

Blade Temperature: Dry cutting can take longer and requires more cooldown time. Dry cutting can cause blades to heat up quickly, potentially shortening their lifespan. Allow the blade to cool off periodically to prevent overheating and possible damage.

Wet Cutting:

Advantages:

Dust Suppression: Wet cutting uses water to cool the blade and suppress dust creation. This not only reduces the inhalation risk of silica dust but also extends the life of the diamond blade.

Precision: The presence of water can reduce friction and make the cutting process smoother, leading to more precise cuts.

Protection for blades: Keeping the surface wet during operation puts less stress on the saw. While these blades don’t have a heat-resistant construction like dry-cutting blades, the water can preserve the segments. With water cooling, the machine has a smaller chance of overheating. Less heat reduces maintenance and increases uptime.

Disadvantages:

Maintenance: Wet cutting requires additional equipment, such as a water pump or a steady water supply, and the water used can create sludge that may need to be cleaned up after cutting.

Potential for damage or chipping: Since wet cutting is more abrasive, it can damage some materials, such as porcelain. It can chip tiles, so you must use an adjustable blade for tile work.

Electrical hazards: The splashing water can create hazards with any surrounding electrically-powered equipment. Remove any nearby machinery which is not water-safe before wet cutting.

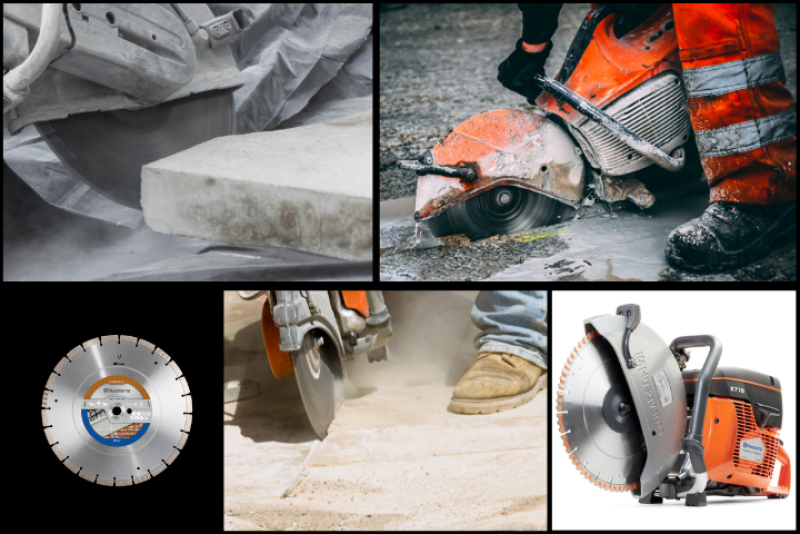

Electric vs. Gas-Powered Stone Saws

When selecting a stone saw, the choice between electric and gas-powered models is often dictated by the job's requirements and the working environment. Electric stone saws are typically easier to set up for wet cutting because they don't emit exhaust and are often designed with built-in water feed systems. On the other hand, gas-powered stone saws offer portability and power but may require a separate water attachment for wet cutting, which can add to the complexity of the setup.

Electric Stone Saws: These saws are ideal for indoor use or in residential areas where noise and emissions are a concern. They offer convenience and are generally lighter and easier to maneuver than their gas counterparts. Electric saws may have less power depending on the model. This might limit their ability to cut through thicker or harder materials.

Gas-Powered Stone Saws: These are the workhorses of the hardscape world. Gas saws provide more power, which translates to faster cutting and the ability to handle tougher, thicker materials. However, they require more maintenance than electric saws, and the emissions and noise levels can be significant.

Stone Saw Blades

The right choice of blade is as critical as the saw itself. Different materials and cutting jobs require specific types of blades:

Diamond Blades: These are the most common, popular, and versatile blades used in stone cutting. Diamond blades come in various types, including segmented, continuous rim, and turbo blades. Segmented blades are ideal for cutting through natural stone and concrete, as they offer the best balance between cutting speed and blade life. Continuous rim blades are designed for materials that require a smoother cut, such as marble or granite. Turbo blades, with their serrated edge, offer a compromise between the cutting speed of segmented blades and the smooth cut of continuous rims.

Abrasive Blades: These are less common but can be used for softer stone or for projects where the finish of the cut is not a primary concern. They wear down more quickly than diamond blades and tend to produce more dust.

Cutting Different Hardscape Materials

The type of stone saw and blade you choose should be matched to the material you are cutting:

Natural Stone: Natural stone such as granite, sandstone, or limestone requires a powerful saw, equipped with a diamond blade. The hardness and irregularities of natural stone can be challenging, so selecting a high-quality diamond blade designed for the specific type of stone is vital. When cutting natural stone, such as granite or sandstone, wet cutting is often preferred to minimize dust and cool the blade, as these materials can be particularly tough on blades.

Precast Stone: Precast concrete pavers or stones are more uniform in composition and often easier to cut than natural stone. An electric stone saw can usually provide the necessary power for cutting precast materials, and a continuous rim diamond blade can ensure a clean, smooth edge. Precast stone or concrete pavers can usually be cut dry unless dust suppression is needed due to job site conditions or specific safety regulations.

404 Stone has both Electric and Gas Powered Stone Saws available for purchase or to rent. Along with a large selection of Diamond and abrasive blades to fit any job requirements.

Safety Reminder: Regardless of the material, always engage in safe operating practices. Cutting stone can produce silica dust, which is hazardous when inhaled. Always work in a well-ventilated area, wear personal protective equipment, and consider using a saw with a built-in water feed to minimize dust.

In conclusion, whether you choose an electric or gas-powered stone saw, select the appropriate blade, and follow safety guidelines, your hardscaping project can progress smoothly and efficiently. Remember, the key to a beautiful and durable hardscape lies in the precision of your cuts and the care in your workmanship. Stay safe, and let every slice be as enduring as the stone it shapes.